Dongguan Jinrui Hardware Products Co., Ltd. is located in Nancheng Industrial Zone, Daojiao Town, Dongguan City. The company was established in 1995 and is a private enterprise with a total investment of more than 200 million yuan. The company covers an area of about 40,000 square meters and has 500 employees.

The company is mainly dedicated to the manufacture of precision hardware accessories in the refrigeration industry, with 20 years of rich experience in hardware stamping development and manufacturing. The company is equipped with training rooms, basketball courts, table tennis courts, reading rooms, and Jinrui Teaching Academy. At present, it has become one of the key suppliers of Panasonic's global household air-conditioning compressors/scroll compressors/auto compressors, Taiwan Ruizhi, Meizhi, Zhuhai Lingda, Gree Daikin, Guangzhou Mitsubishi, Galanz compressors, etc. It is also the main partner of Sweden Match Group, Spain Lighter Manufacturing Co., Ltd., and France BIC Group in China.

In September 2014, Jinrui's new plant was put into production, adding a new reservoir manufacturing project. At present, the main customers are Zhongshan Galanz and Malaysia Panasonic. Company production distribution: the new factory specializes in the production of stamping parts and reservoirs, and the main factory specializes in the production of pipe fittings (exhaust pipes, ducts, tapered pipes)

Product description

Silence cover

Production process: single die/continuous die

Function: compressor silencer

Reference price: 0.2896~0.724

Minimum order quantity: 500 sets

Production capacity:

1. Single die production of multi-process products 348480 units/day

2. Continuous mold production of multi-process products 554,400 units/day

The company's strength advantages: the ability to independently design, develop and produce molds, receive customer drawings, and the cycle from mold opening to product production is 45 days;

Auto products

Production process: single die/continuous die

Function: car seat accessories

Use position: car seat cushion, back, headrest fixing parts

Specification and shape: mold according to customer's drawing requirements

Reference price: 0.4344~1.1584 (USD)

Minimum order quantity: 500 sets

Production capacity:

1. Single die produces 59136 sets of multi-process products per day

2. Continuous mold production of multi-process products 50688 sets/day

Company strength advantage: the ability to independently design, develop and produce molds, receive customer drawings, and the production cycle from mold opening to product production is 45 days

Copper pipe fittings

Production process: semi-automatic production process/automatic integrated production process

Function: compressor exhaust system, pump body connecting pipe, suction outer pipe connector

Use location: associated link of compressor external equipment

Specification and shape: mold according to customer's drawing requirements

Reference price: 0.1448~0.8688 (USD)

Minimum order quantity: 500 sets

Production capacity:

1. The production capacity of semi-automated production process is 207,429 units/day

2. Automatic integrated process production capacity 250337 units/day

Company strength advantage: the ability to independently design, develop and produce molds, receive customer drawings, and the production cycle from mold opening to product production is 45 days

Steel pipe fittings

Production process: tube expansion grinding/stretching process

Function: compressor exhaust system, pump body connecting pipe, suction outer pipe connector

Use location: associated link of compressor external equipment

Specification and shape: mold according to customer's drawing requirements

Reference price: 0.1448~0.5792 (USD)

Minimum order quantity: 500 sets

Production capacity:

1. The production capacity of pipe expansion and grinding process is 230,400 units/day

2. The production capacity of stamping and drawing process is 177,408 units/day

Company strength advantage: the ability to independently design, develop and produce molds, receive customer drawings, and the production cycle from mold opening to product production is 45 days

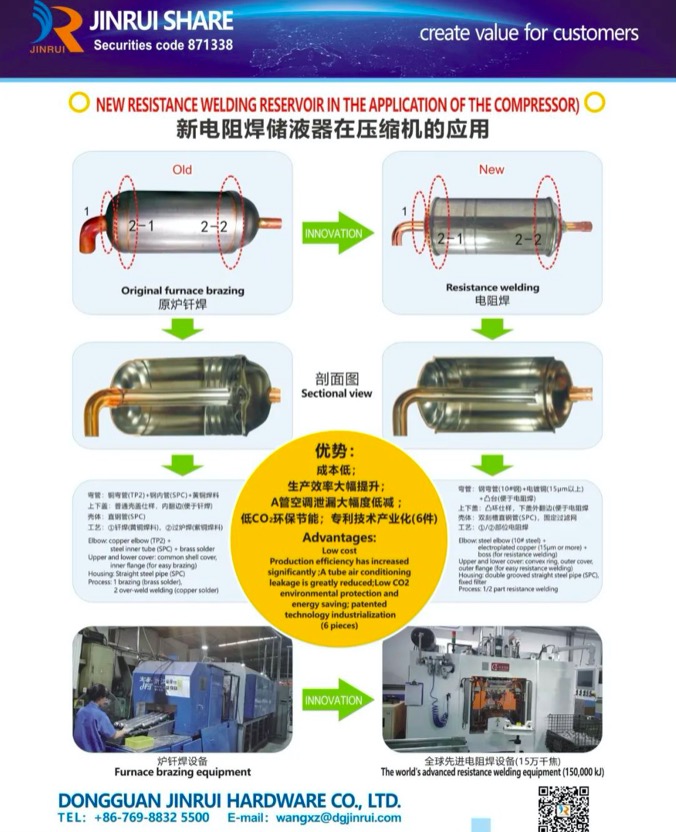

Reservoir

Production process: three-stage, spinning furnace welding/flame welding/fiber welding

Function: compressor refrigerator oil, refrigerant storage tank

Use location: associated link of compressor external equipment

Specification and shape: mold according to customer's drawing requirements

Reference price: 0.724~2.896 (USD)

Minimum order quantity: 500 sets

Production capacity:

1. The production capacity of furnace welding, flame welding and fiber welding is 20,000 sets/day

2. Resistance welding process production capacity is 20,000 sets/day

Company strength advantage: the ability to independently design, develop and produce molds, receive customer drawings, and the production cycle from mold opening to product production is 45 days

In 2013, it was recognized as a national high-tech enterprise. The company has obtained 65 patents, including 32 invention patents and 33 utility model patents. In 2018, it won the third prize of Dongguan Science Progress, and it is the only enterprise in Daojiao Town to receive this award.

Development vision: the environment changes because of me!

For individuals: personal spiritual needs and family living environment and quality are improved;

For enterprises: create a positive growth environment, a good working and living environment;

To society/customers/family: Bring a more environmentally friendly, energy-saving, safer and more comfortable environment.

Enterprise mission: to be the leader of the refrigeration industry!

With technological innovation as the core, continue to provide customers with the most complete solutions and products, and create maximum value together!

Values: honesty, responsibility, obedience, caring!

Integrity: honesty and integrity, keeping promises;

Responsibility: I admit that it is my ability and do not make excuses; commitment is my structure and guarantees the results;

Obey: Obey orders and obey orders;

Caring: speak with heart and do things with love.

RACC2021 Global Promotion Continues